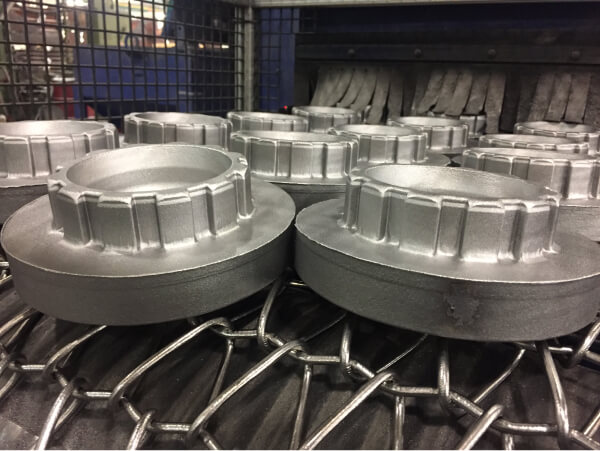

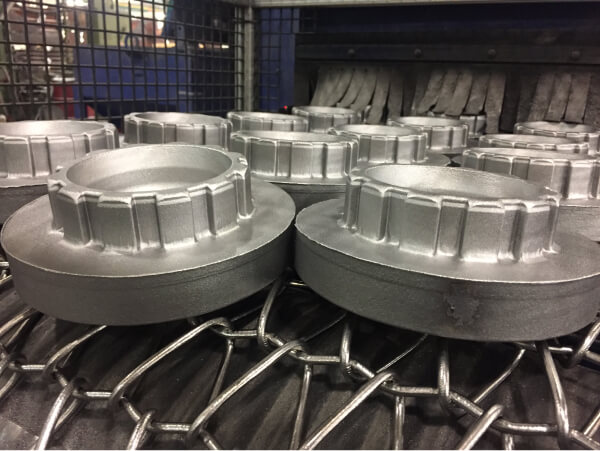

Forging shapes metal under high heat and pressure. However, this process often leaves a layer of scale on the metal's surface. This scale, varying from brittle to sticky, must be meticulously removed before any subsequent operations. Understanding the descaling process is vital for those in the forging industry, particularly for maintaining the quality and integrity of metal parts.

The Challenge of Scale Formation

During the forging process, metals are exposed to extremely high temperatures. This exposure results in the formation of a layer of scale, primarily composed of iron oxides. The scale's characteristics can vary; it might be brittle and easily detachable or sticky and challenging to remove. Regardless of its nature, scale presents a significant challenge as it can affect the metal's surface quality and interfere with further processing like welding or painting.

Effective Descaling Techniques

Removing scale is not just about maintaining aesthetics; it's crucial for ensuring the functionality and durability of the forged part. Here, products like S390 to S660, GP18 to GP12, and HPG come into play. These abrasive materials are used in blasting processes, effectively removing scale without damaging the underlying metal.

1. Choosing the Right Abrasive Media

The choice of abrasive media (S390 to S660, GP18 to GP12, HPG) is crucial. Factors like size, hardness, and material composition of the media must align with the nature of the metal and the scale. For instance, a harder abrasive may be necessary for tougher scales, while a softer material might suffice for less adherent types.

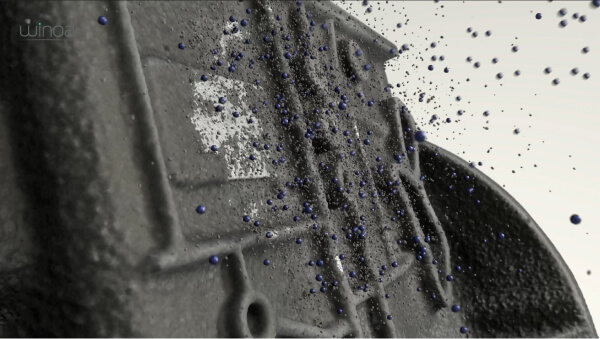

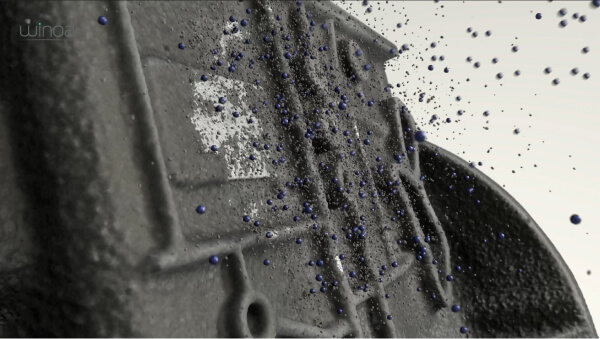

2. Blasting Techniques

Blasting is a common and effective method for descaling. It involves projecting abrasive media at high velocity towards the metal surface. This process not only removes scale but also prepares the surface for further treatments. The effectiveness of blasting depends on factors like the angle of impact, velocity of the media, and duration of blasting.

3. Ensuring Uniformity and Safety

Uniform descaling is crucial for maintaining the metal's integrity. Inconsistent descaling can lead to weak spots or stress concentrations in the metal. Additionally, safety measures must be in place to protect operators from hazards associated with blasting, like flying debris and dust.

Conclusion

Descaling in forging is a main step in ensuring the quality and functionality of metal parts. By understanding the importance of this process and the effective use of abrasive media, professionals in the forging industry can achieve superior results, enhancing the longevity and performance of metal products.